Industrial Laser Safety Technician Certification

What does it mean to be laser certified?

Industrial Technician Certification - $69

Through our Industrial Laser Safety Curriculum, your employees will learn everything they need to know about the following:

- How lasers work

- Why wavelength is important

- Personal Protective Equipment

- Non-ionizing radiation

- Laser Hazard Classes

- Beam contact hazards

Being “laser certified” in the context of Industrial Laser Safety Technician/Operator Certification means that an individual has completed specific training and certification processes to ensure they have the knowledge and skills necessary to safely operate and manage laser systems in an industrial setting. This certification validates that the person understands the potential hazards associated with laser use and is competent in implementing safety protocols to mitigate these risks. Here’s what it typically entails:

Key Components of Laser Certification

for Industrial Safety Technicians/Operators

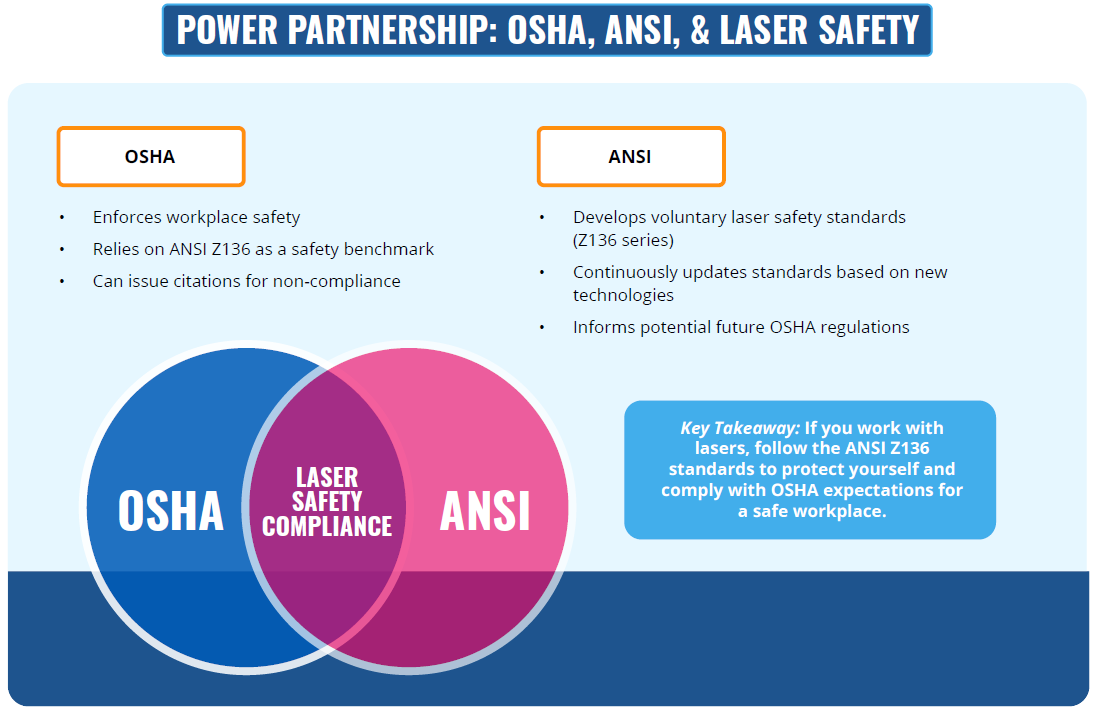

Regulatory Compliance

OSHA Standards: Knowledge of relevant OSHA regulations and guidelines related to laser safety.

ANSI Z136.1 Standards: Understanding and applying the ANSI Z136.1 standard for the safe use of lasers in industrial environments.

Certification Process

How to get certified for laser safety

Certification Benefits

Why it is important to become laser safety certified

Responsibilities of Certified Technicians/Operators

What is your role after becoming certified?

Operation and Maintenance:

- Safely operate and maintain industrial laser systems according to manufacturer guidelines and safety standards.

- Perform regular inspections and maintenance to ensure the equipment is functioning safely and efficiently.

Safety Implementation:

- Implement and enforce safety protocols, including the use of PPE and engineering controls.

- Conduct hazard evaluations and update control measures as necessary.

Training and Supervision:

- Provide laser safety training to new operators and ensure ongoing education for existing staff.

- Supervise the use of laser systems to ensure compliance with safety procedures.

Incident Management:

- Respond to laser-related incidents, conduct investigations, and implement corrective actions to prevent future occurrences.

Summary

Being laser certified as an Industrial Laser Safety Technician/Operator means completing a rigorous training program, passing a certification exam, and gaining practical experience to ensure the safe operation of laser systems. Certification validates the individual’s expertise in laser safety, hazard evaluation, regulatory compliance, and emergency response, making them a vital asset in maintaining a safe industrial work environment.