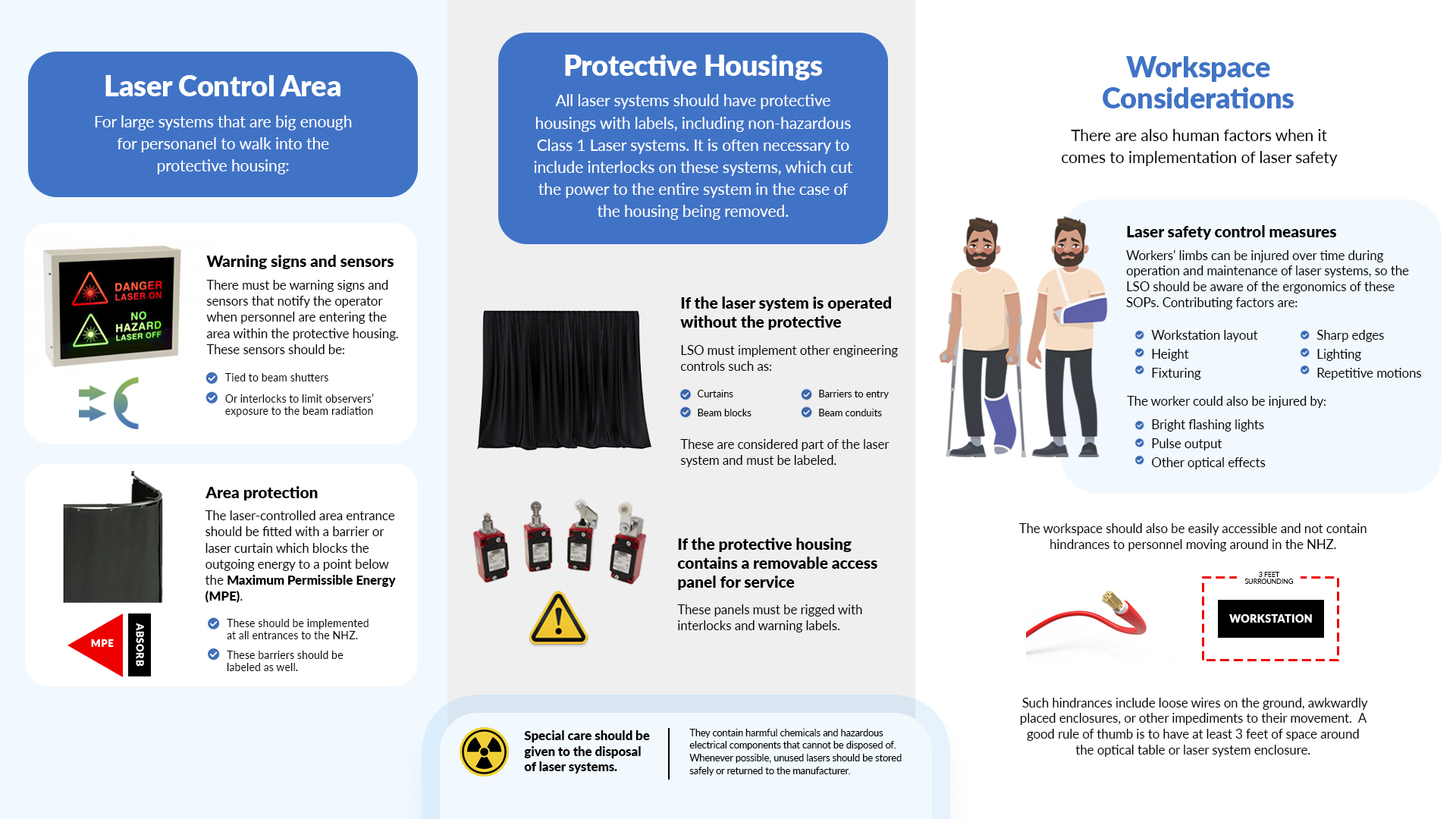

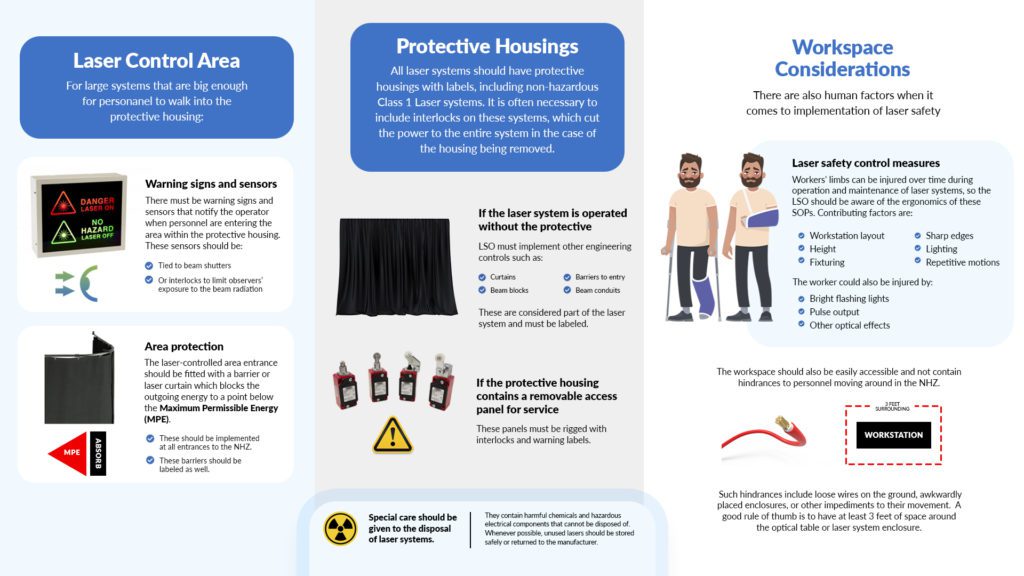

Protect Your Laser Control Area in the Workplace

The laser control area in your workplace should be properly labeled, employ engineering controls and provide area protection limiting energy below Maximum Permissible Energy (MPE). The Laser Safety Officer (LSO) must ensure that the Nominal Hazard Zone (NHZ) is labeled and that appropriate protection measures are in place at all entrances.

Protective Housing Guidelines

All laser systems should have protective housing with labels, including non-hazardous Class 1 laser systems. It is often necessary to provide interlocks on these systems , which cut power to the entire system when the housing is removed.

If the laser system is operated with the protection, the LSO must implement other engineering controls such as:

- Curtains

- Beam blocks

- Barriers to entry

- Beam conduits

These are all considered part of the laser system and must be labeled.

If the protective housing contains a removeable access panel for service, there panels must be rigged with interlocks and warning labels.

Laser Control Area Guidelines

For larger systems that are big enough to walk into the protective housing, there are a couple extra safety issues to consider. The LSO must insure that appropriate measures such as the following are in place.

Warning signs and sensors – There must be warning signs and sensors that notify the operator when personnel are entering the area within the protective housing.

These sensors should be:

- Tied to beam shutters

- Or use interlocks to limit observers exposure to the beam radiation

Area protection – The laser-controlled area entrance should be fitted with a barrier or laser curtain which blocks the outgoing energy to a point below the Maximum Permissible Energy (MPE).

- These protection measures should be implemented at all entrances to the Nominal Hazard Zone (NHZ).

- These barriers should be labeled as well.

Workplace Considerations

There are also human factors that come into play in the implementation of laser safety. Worker’ limbs can be injured over time during operation and maintenance of laser systems, so the LSO should be aware of the ergonomics of these Standard Operating Procedures (SOPs).

Contributing factors are:

- Workstation layout

- Height

- Fixturing

- Sharp edges

- Lighting

- Repetitive motions

The worker could also be injured or their focus distracted by:

- Bright flashing lights

- Pulse output

- Other optical effects

The workplace should also be easily accessible and not contain hinderances to personnel moving around in the Nominal Hazard Zone (NHZ).

Such hinderances include loose wires on the ground, awkwardly placed enclosures, or other impediments to their movement.

A good rule of thumb is to have at least 3 feet of space around the optical table or laser system enclosure.

Laser System Disposal

And finally, special care should be given to the disposal of laser systems. They can contain harmful chemicals and hazardous electrical components that cannot be disposed of. When ever possible, unused lasers should be stored safely of returned to the manufacturer.

How Laser Safety Certification can help

Reach out to us if you would like this infographic and we will send it to you. It comes in two versions you can print out or apply as needed. We have other laser safety infographics on other blogs in this series, so please check them out too. Just email us at: info@lasersafetycertification.com or use the easy links on our homepage.

At Laser Safety Certification, we have laser safety courses and Laser Safety Officer (LSO) certification programs to make sure your team are correctly using lasers and your customers are protected. We provide certification programs that follow the OSHA recommendations and ANSI guidelines for laser safety. This infographic is a small part of that. We can help with your laser safety training needs if you are using lasers in manufacturing or production applications, or if you are using them in the medical, veterinary, cosmetic or healthcare fields and have concerns about your patient safety.

For more information about industrial laser safety, check out our courses for Industrial Laser Safety and Industrial LSO certification. For more information about medical, health care, or veterinary laser safety, check out our courses for Healthcare Laser Safety and Healthcare LSO certification today. For cosmetic laser safety, see our Cosmetic Laser Safety and Cosmetic LSO Certification courses for more information. We also have an FAQ section with common answers about our courses, certification options and kit offerings for your LSO to manage your own safety program.

Good post.

Comments are closed.